Industrial

Special-Purpose Solutions and Small Batch Series

Service

Mulitvendor Principle

Let us support you in finding the optimal material for your application, and you will benefit from our profound know-how!

Development

Together with you we develop custom-made solutions. Here, we attach great importance to efficiency.

Sampling

We provide proficient advice and support from the generation of first prototypes up to initial sampling, including all required IMDS entries and ISTRs. Our lean structures allow us to be flexible, accurate and quick-acting.

Production

We manufacture individual orders as well as small-scale and large-scale series, invariably with the claim of maintaining our consistently high quality. Click here to look and see our wide range of fashioning and processing options: Processing

RANGE OF APPLICATIONS

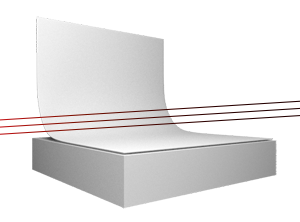

SEALING

Our materials are utilized for sealing purposes in a wide variety of interior as well es exterior applications. They help prevent the non-desirable entry or escape of air or liquid agents.

Examples

- Sealing of air piping systems for interior applications

- Sealing of connections or junctures for exterior applications

ACOUSTIC INSULATION

For the quietening of sounds we apply open-celled sonic action PU foam materials, if applicable with performance-enhancing surfaces such as, e.g. thin PU foils, textile surfaces or heavy-layer materials.

Examples:

- Sound proofing for car wheel arches

- Sound proofing B-pillar

Special-Purpose Solutions

As a multivendor specialist for customized applications we provide innovative and intelligent solutions for a wide variety of industrial purposes and support our customers through all stages from project development to production.

Examples:

- Packaging made of PE/PU, milled, foamed or punched

- Special-purpose solutions for acoustic applications

- Small-scale series

Materials

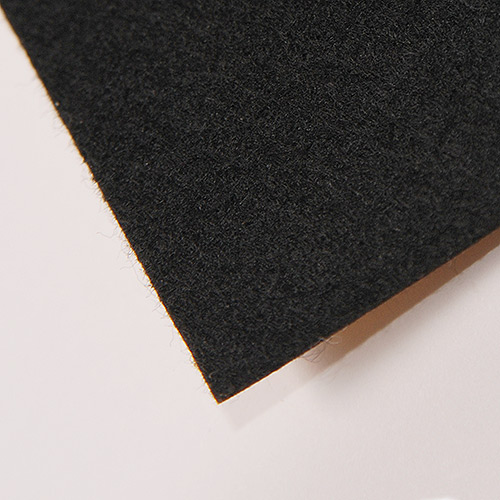

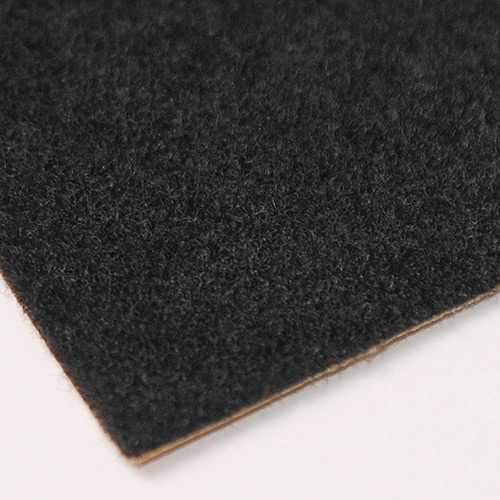

Technical textiles

We fashion textile materials for car interior applications. Here they are frequently utilized as adhesive tapes to help prevent unpleasing noises or guard against frictional wear.

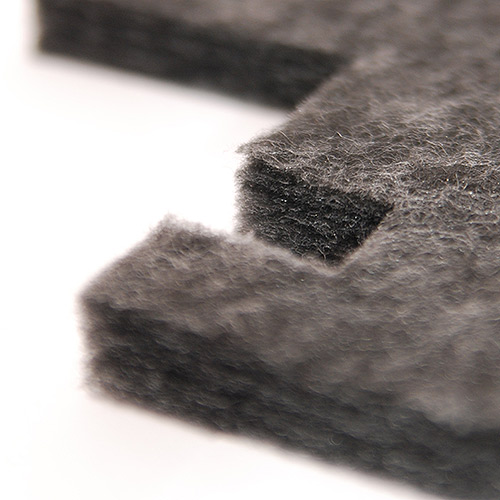

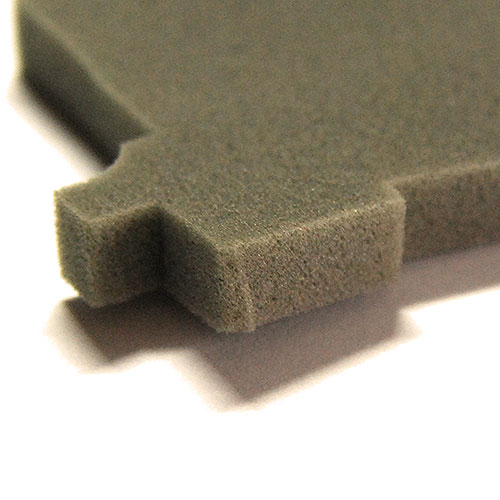

Cellular materials

The range of cellular materials covers an extensive portfolio. These materials are often used as draft or noise insulation, however, are characterized by their cellular structure and the ……thus combined.

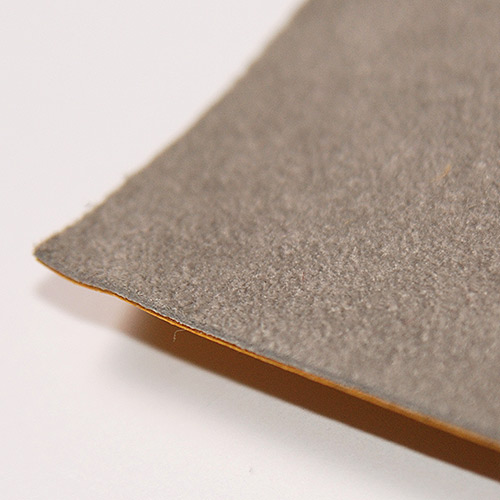

Solid materials

In most cases, solid materials are utilized as flat packing or O-seals.

PE (Polyethylene)

Als Plattenware für einfache Gleitbeläge als Stanzteil oder gefräst. Als UHMW Folie: Aus massivem Material geschält und im Spezialverfahren selbstklebend ausgerüstet.

Fashioning

TAPE CUTS

We fashion roll materials to become customized tapes and adhesive tapes. Here it is actually possible to find the optimal material and matching adhesive film to suit almost any intended use.

Suitable for: Felt, nonwoven fabric, velour, Alcantara

Punching, cutting

Sheetware is processed by means of our punches which can handle sheets with up to 100 mm thickness. Particularly suited for small and medium-sized quantities.

Suitable for: Felt, nonwoven fabric, velour, Alcantara, PU, PE, PP Kiss-cut

Kiss-Cut

Here, the material is merely punched up to the carrier of the adhesive tape thus making subsequent processing steps a lot easier. Here, unwanted remains can already be removed during the production process. Particularly suited for medium-sized to large quantities.

Suitable for: Felt, nonwoven fabric, velour, Alcantara, PU, PE, PP

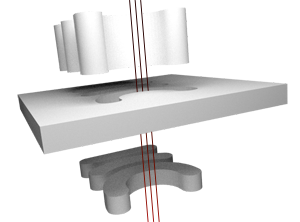

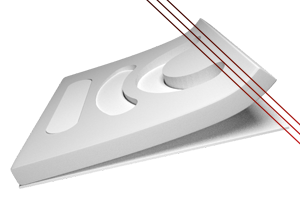

Shaped PUR Foam

Our machinery systems enable us to manufacture shaped PUR foam parts with or without filler agents. The minimum/maximum weight for an individual part ranges from approx. 10 grams up to approx. 10 kgs.

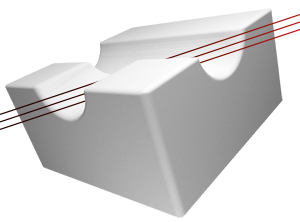

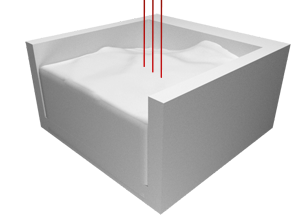

PUR-Casting

Apart from the production of shaped parts out of cellular foam, we also manufacture cast shapes of a more solid consistency. Particularly suited for the production of contour seals, highly stressed cushions or similar purposes.